History in action: the first Black Kiriko

Tajima Glass Co.,Ltd.

Craft Type: 22Edo Kiriko

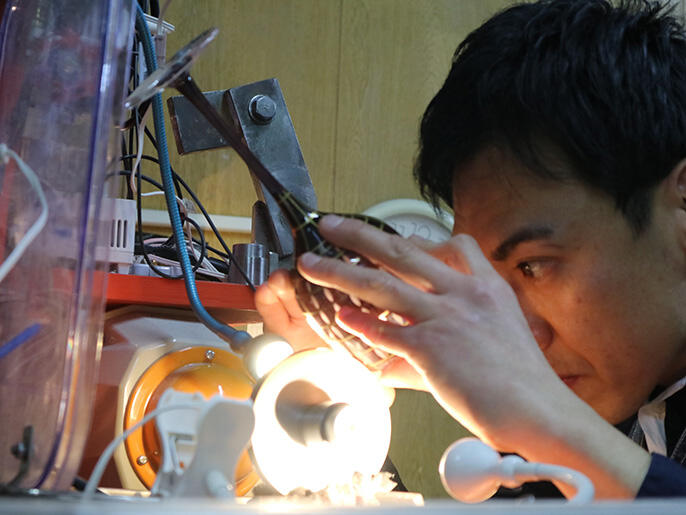

At the Tajima Glass factory, there is heat. Silica sands melted at 1400℃ wait to be processed, red as the sun. The melted glass is wrapped around a steel pole, and is then used in a variety of techniques. Firstly there is 'blown glass' using a pole with a cavity to input air and create the shape. The 'air blown' technique is the name given to the process of the pole revolved in the air with the glass shape altered by tools. 'Mold blowing' is where wooden or gold molds are added to the glass while the pole is set in its revolving pattern. The craftsmen at the Tajima factory have mastered all of the traditional Edo glass techniques. Edo Kiriko cut glass is made using coloured glass, cut into intricate patterns. Base glass sealed, or 'covered' with coloured glass: so called 'kise glass' ('covered glass') is also a process undertaken at Tajima. This covered glass is then supplied to many Edo Kiriko workshops. In the history of this work, the first black covered glass was the achievement of Tajima. Although a similar black glass has been made before in the Satsuma cut glass tradition (in south Japan), Tajima's version is thinner at 0.2-0.3mm. This thinness makes a colour difficult to reproduce, and to consistently achieve the effect Tajima spent one year refining their process. The first 'black kiriko' in the Edo Kiriko tradition, is of historic importance. The outstanding skill and passion of Tajima Glass toward their material, makes them a leader in the field.

Craftsman Profile

| Craftsman Name | Tajima Glass Co.,Ltd. |

|---|---|

| Address | 4-18-8,Matsue,Edogawa-ku,Tokyo 132-0025 |

| TEL |

+81-3-3652-2727 Fax:+81-3-3651-2229 |

| Representative | Daisuke Tajima |

| E-mail address | info@tajimaglass.com |

Craftsmen Specializing in 22Edo Kiriko